Chlorine Tablets are an inexpensive, versatile, broad-spectrum disinfectant widely used in various industries, from medical facilities to food production. In this blog, you’ll discover the essential information about chlorine tablet solutions, including how to prepare them, their effectiveness, and their advantages over other disinfectants.

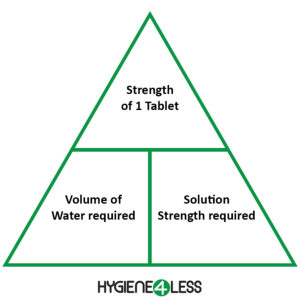

Calculating the Strength of a Chlorine Tablet Solution

Understanding how to create the right strength of chlorine solution for the intended purpose is crucial for effective disinfection and any due diligence you may be required to demonstrate. We have created the “PPM Triangle” to help you calculate correctly.

For ease of use: ‘ppm’ means parts per million. Water volume is calculated in litres or part thereof.

Here’s how it works:

- To calculate the Volume of Water required:

- divide the strength of 1 tablet by the ppm required

- To calculate the Solution Strength (ppm) required:

- divide the strength of 1 tablet by the volume of water in your receptacle

Examples:

- To establish the Volume of Water required: the strength of 1 tablet is 1,000ppm and solution strength required is 500ppm. Therefore 1,000 / 500 = 2 litres

- To work out the Solution Strength: there is 1 tablet with a strength of 1,000ppm in 100ml (0.1 litres) of water. Therefore 1,000 / 0.1 = 10,000ppm

- To establish the Overall ppm required and therefore the number of Chlorine Tablets to use: You have a 40 litres sink and you require a solution strength of 100ppm to soak salad: therefore 40 x 100 = 4,000 (4 x 1,000ppm tablets)

Steps to Create a Chlorine Tablet Solution

Creating a chlorine tablet solution is a quick and simple process:

- Disinfection is usually done with cold water (20oC). We recommend you pre-dissolve the tablet/s in a small volume of warm (not hot) water as this will speed up dissolution.

- Next, when the tablet/s have dissolved, make up the solution to the desired volume required with cold tap water. This effectively mixes up the solution and ensures even distribution of the chlorine in the water.

- Generally speaking, the solution strength does not need to be tested. If in doubt, the strength of the solution can be checked using Chlorine Indicator Test Strips. These are a fast and simple dip and colour change comparison method – please note that using chlorine indicator test strips are for a guide only.

- After dipping the test strip into the solution, compare the colour presented on the strip with the colour chart provided (located on the side of the test strip packaging).

- If the chlorine solution has not been contaminated by dirt or debris and the risk is relatively low, in some cases it could be topped up with the addition of more tablets. However, the best practice is always, if in doubt, discard the solution and start again.

Stability of Chlorine Tablets and Made-up Solutions and where to use them

Chlorine Tablets are inherently stable if stored correctly in a cool, dry place away from direct sunlight or heat source. For example, in a sealed tub or pouch. It is not unusual for Chlorine Tablets to still give an accurate solution of chlorine after 5 years storage. We put a 3 year expiry date on our standard packaging.

When made into a solution, best practice is to make a fresh solution every 24 hours or every shift. If you encounter a solution that appears contaminated (colour change, murky or visible debris) then it should be discarded and a new solution made up.

Solutions made from Chlorine Tablets are very versatile and can be used on virtually any hard, non-porous surfaces including on most metals. The chlorine solutions in general, are no more corrosive than tap water*1.

Unlike Sodium Hypochlorite solutions, Chlorine Tablet Solutions are used at very low concentrations, typically 0.1% strength for disinfection in Hospitals (1,000ppm), so any unused solution can be safely discarded by sluicing into sinks, toilets or drains.

Chlorine vs. Other Disinfectants

Chlorine is one of the broadest spectrum biocides available. It will kill Bacteria (including Legionella and Food Poisoning Bacteria), Viruses (including Coronavirus), Fungi, Yeasts and even Spores. It is one of the very few disinfectants that can be classed as a sterilant.

There are many other types of Biocides including:

QACs (Quaternary Ammonium Compounds), which are commonly found in disinfectant wipes and sprays, have a far narrower biocidal range and limited virucidal ability. There is a growing trend away from QACs, particularly in professional food production environments because they leave a residue that can build-up over time.

Peracetic Acid and Hydrogen Peroxide have a broad spectrum of activity and are biodegradable. But there are concerns over their corrosive nature to surfaces, eyes, skin and respiratory tract, particularly when concentrated. It is more expensive than chlorine and can require longer contact times during disinfection tasks.

Alcohol based disinfectants are fast acting with fairly broad spectrum of activity, however they are very flammable and do not kill C. difficile or Spores.

Comparing Effervescent and Detergent Chlorine Tablets

Both of our Prosan Effervescent Chlorine Tablets and Prosan Detergent Chlorine Tablets contain Troclosene sodium (NaDCC) and produce predominantly Hypochlorous Acid (HOCl) when dissolved in potable (tap) water. Each type of tablet gives a 1,000ppmavailable chlorine solution per 1 litre of water.

The main difference between the two is that our Detergent Chlorine Tablets contains a low foaming anionic surfactant, which helps clean surfaces and suspend the dirt in solution whilst disinfecting. This one-stage sanitiser can also reduce operator cleaning time.

We recommend our Prosan Detergent Chlorine Tablets are used as a one-stage sanitiser for hard surfaces in Care, Catering, Food Production or Hospital Disinfection.

Prosan Chlorine Effervescent Tablets are more suitable where “Terminal disinfection” of hard surfaces or machinery is required after cleaning. Also, they are suitable for Water Purification.

Chlorine remains the backbone of UK NHS disinfection practices due to its versatility, affordability, and reliability. By understanding how to prepare and use chlorine solutions correctly, you can ensure reliable performance, due diligence and optimal disinfection of hard surfaces in a variety of industries.

*1 Corrosion tests were carried out using a 1,000ppm solution for 24 hour emersions of various metals including mild steel, stainless steel etc.